When splicing electrical wires together it is important to use the right connectors to make safe and stable connections. Wing wire connectors are a fast and easy way to make secure connections that won’t loosen or come apart. There are many reasons to connect existing wires to new wires, or create altogether a new wire management plan to expand or complete a complex installation. In most cases, electrical wires are stripped of their insulation in order to connect two or more wires together, exposing wire ends that need to be ‘capped’ to secure the connection and prevent fires or electrical shortages.

Winged Wire Connectors provide more grip when tightening connections

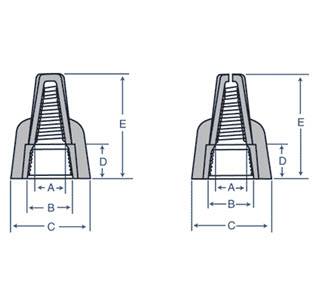

The importance of spicing wires correctly and safety cannot be overstated. A winged wire connector is used to secure two or more electrical wires together in order to create a continuous flow of electricity. A winged twist on connector is similar to a standard twist on connector, the difference is the ‘winged’ edges give you more torque for tightening or removing the connector. They are quick and easy to use in new installations and the extra rigid material on the side of the wire connector makes it easier to remove when modifying existing wire connections.

Winged wire connectors are made from a rigid, flame resistant insulating thermoplastic material that is easy to handle and doesn’t break when you tighten it. It is also a faster installation process and easier than traditional methods of soldering wires together. The outside plastic encases a tapered metal square spring insert which threads the wires together and securely bonds them. To use a wing connector, first twist the exposed wires together and then insert the wires into the metal insert and twist them tightly, until a secure connection is made that won’t pull apart. The electrical continuity is maintained by the wire to wire contact that is made by twisting the wires and connector together, and by the contact made with the metal spring insert. The winged connector make installations faster to do, and provide more stability than standard twist on connectors.

Make sure you use winged wire connectors to ensure tight electrical connections. There are instances where you have to provide extra protection to your electrical connection, such as preventing other wires to touch exposed metal surfaces which could be a big fire hazard. Protecting your electrical connections in a safe and reliable way also helps to prevent short circuits or other faults. The wing connector is made of thermoplastic UL94V-2 flame retardant material that has a temperature rating of 221° F (105°C) and is UL listed and CSA approved.

Getting the right Winged Wire Connectors for AWG wiresWinged connectors are color coded to represent the number of AWG wires and the size range of AWG wires that the individual wire connectors can handle. Industry standards for electrical connections require that the right connectors are used with the right wire capacity. Choosing the right winged wire connector follows the color coding set forth by the NEIS (National Electrical Installation Standards), which state that only wires of the same AWG size be used together, and the color corresponding connector is to be used to secure the wire ends. This industry standard is in place to prevent electrical current from overheating or damaging the wire connections.

Visit the Electrical Basics website to find the right winged wire connector to fit your electrical wiring needs. You can find the AWG size wire range and the number (maximum and minimum) of AWG wires that can be used for each winged wire connector available on the Electrical Basics website. There are options that and quantities available to support a variety of small to large jobs. Call us at 877-947-8437. and our customer support team can help you to determine the right winged twist on wire connector to use for your application.

Please Remember to Turn Off the Power When Working on Live Circuits!